Les iPhone 7 et 7 Plus sont disponibles depuis plus de 20 jours. Comment allez-vous traiter votre iPhone 7 ou 7 Plus cassé ? En fait, nous avons déjà publié plusieurs articles concernant les conseils de remise à neuf des écrans LCD pour certains modèles phares d'Apple et de Samsung. Mais aujourd'hui, vous avez la possibilité de découvrir en avant-première les dernières techniques et astuces de reconditionnement des écrans LCD cassés. Il s'agit du tout dernier modèle d'Apple, l'iPhone 7 Plus.

Ce processus de remise à neuf comprendra certains des éléments recommandés suivants machines de remise à neuf d'une performance stable et d'une facilité d'utilisation, ainsi que de matériaux et outils de réparation . Savourons maintenant le plat principal, étape par étape.

Test de l'écran brisé

Tout d'abord, vous avez besoin d'un iPhone 7 Plus LCD dont la lentille en verre est cassée mais dont l'écran tactile et l'écran LCD fonctionnent correctement. Installez l'écran LCD sur la plaque de la carte mère, puis testez si l'écran, l'écran tactile et la fonction tactile 3D fonctionnent correctement.

Démontage de la lunette

Retirer l'écran LCD du téléphone, couper les 4 coins du cadre avant avec un fer à souder chauffant. Collez du ruban adhésif sur l'ensemble de la lentille en verre pour éviter les problèmes qui pourraient survenir lors d'opérations ultérieures. Poser l'écran LCD sur Séparateur LCD manuel (80-90℃) et chauffer pendant environ 15s. Appuyez sur le bouton Start et retirez le cadre de la lunette. Retirez ensuite la colle adhésive de la lunette avec une lame de rasoir.

Séparation du verre

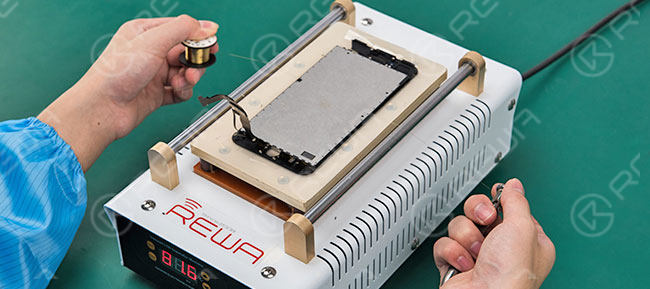

Intégrer le fil de découpe de l'or dans le bas de l'écran LCD, tirer de droite à gauche jusqu'à ce que le verre se sépare.

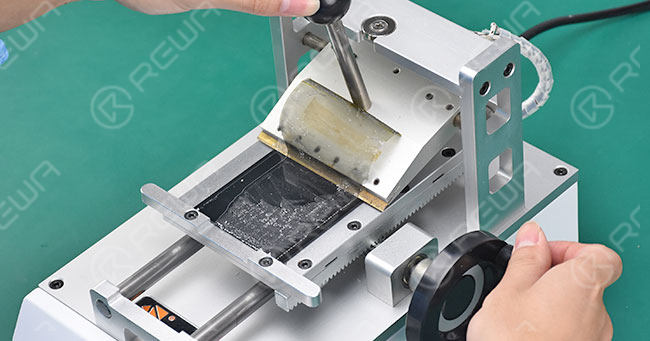

Enlèvement de la pellicule POL

Allumer Machine à enlever la colle LCD et préchauffer pendant 5 minutes (170-180℃), puis retirer le film POL.

Retrait de la colle

Brosser quelques Nettoyeur LCM sur l'écran LCD et enlever les résidus de colle. Éliminez complètement les résidus avec du N-hexane.

POL Pelliculage de films

Mettre l'écran à cristaux liquides en marche Machine à plastifier les films POL / OCA et l'aligner avec un nouveau morceau de film POL. Appuyez sur le bouton Pump Down, absorbez-le sur le panneau. Nettoyez à nouveau l'écran LCD et décollez le film protecteur à l'aide de l'autocollant Easy Tear. Appuyez sur le bouton Membrana Tectoria(Laminating) pour lancer la plastification du film POL.

Colle OCA Contrecollage

Déchirer le premier film de protection et aligner la colle OCA sur le LCD. Appuyez sur le bouton "Pump Down" pour absorber la colle OCA. Déchirez le film protecteur à l'aide de l'autocollant Easy Tear, puis passez à la stratification de la colle OCA.

Stratification du verre

Placez l'écran LCD dans aligner le moule et déchirez le film protecteur de l'OCA. Alignez l'écran LCD avec la lentille en verre intégrée et le cadre de la lunette. Déchirez le film de protection de la lentille en verre. Placez l'écran LCD dans le moule de stratification, puis mettez-le dans la machine 4 en 1 de stratification du verre sous vide et d'élimination des bulles d'air. Appuyez sur le bouton Start et commencez le laminage du verre. Retirez-le après le laminage du verre (environ 30s à 42℃).

Elimination des bulles

Poser l'écran LCD sur l'étagère en fer, fermer la porte de la cabine et appuyer sur le bouton de démarrage. Une fois l'élimination des bulles terminée (environ 10 minutes à 35℃), appuyez à nouveau sur le bouton et attendez que la jauge indique 0. À ce moment-là, ouvrez la porte et retirez l'écran LCD.

Remplacement de l'éclairage arrière

Retirez l'adhésif du point de soudure à l'aide d'une pince à épiler. Détachez le point de soudure à l'aide du fer à souder. Placer l'écran LCD sur Plate-forme de chauffage pendant 20 à 30 secondes, puis détachez l'unité de rétroéclairage couche par couche. Enlevez la colle. Nettoyez l'écran LCD avec du N-hexane, enlevez le film protecteur sur l'écran LCD. Unité d'éclairage arrière . Alignez-le sur l'écran LCD, puis soudez le point de soudure à l'aide d'un fil de soudure (veillez à ce que le point d'étain soit saturé). Collez un nouvel adhésif sur le point de soudure.

Nouveau test

Connectez l'écran LCD à la carte mère, puis testez à nouveau l'écran, la fonction tactile 3D et la fonction tactile.

Remarque : 1 L'unité de rétroéclairage ne doit être remplacée que lorsqu'elle présente des problèmes de dégâts des eaux, de taches de poussière, de taches lumineuses et de défaillance du toucher 3D, etc. 2 L'utilisation d'une lentille en verre intégrée avec le cadre de la lunette rend inutile l'étape d'assemblage de la lunette dans ce processus de remise à neuf.

C'est à ce moment-là qu'il faut s'arrêter. En effet, à ce stade, l'iPhone 7 Plus fissuré a été remis à neuf avec succès. Si vous recherchez une machine de reconditionnement d'écrans LCD, des matériaux, des vidéos de démonstration et une assistance technique, n'hésitez pas à nous contacter à l'adresse suivante info@rewatechnology.com ou visitez la boutique en ligne à l'adresse suivante shop.rewa.tech , ou bien regardez la vidéo suivante sur notre chaîne YouTube exclusive.

Vous souhaitez commander nos produits ? Veuillez nous contacter :

PRÉVENTIONS Skype : rewatech

Courriel : service@rewa.tech

APRÈS-VENTE Skype : support-rewatech

Courriel : support@rewatechnology.com