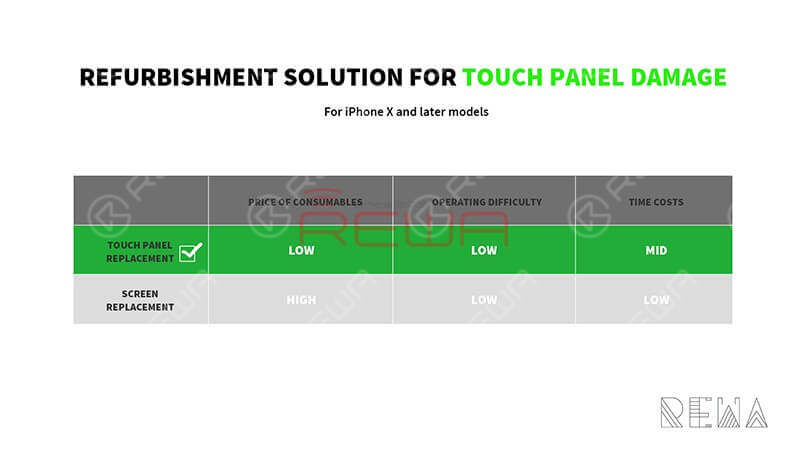

Most of the time the touch issue of iPhone X and above is a screen/motherboard issue. For touch issues caused by screen malfunction, a screen replacement is usually the solution adopted by repair shops. The operation of screen replacement is simple but the price of a new screen is high. It’s time for you to make a change and stand out from competitors in your city with this brand new and cost-effective refurbishing solution – touch panel replacement. Before we introduce the new solution, let’s check out the difference between screen replacement and touch panel replacement.

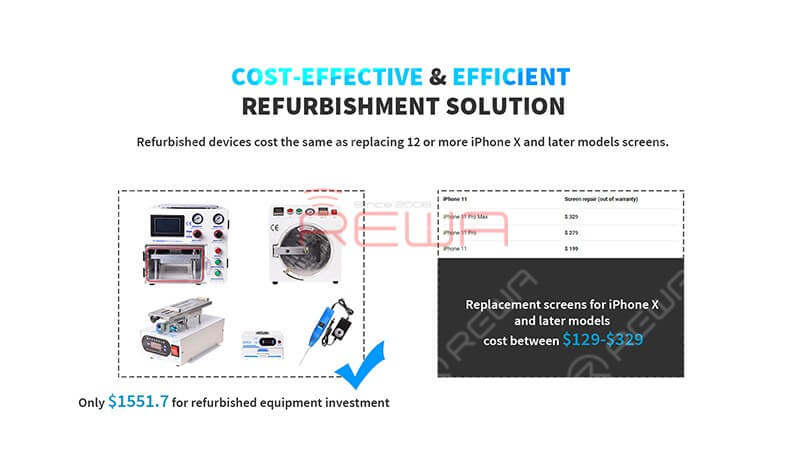

We can see from the figure above that the touch panel replacement solution helps repair shops save more money than the other one. This Refurbishing Solution mainly uses the following equipment:

Rotatable Curved Screen LCD Separating Machine

Máquina laminadora de pantallas curvas

Máquina de eliminación de burbujas

iPhone 11 PRO MAX Touch Screen Digitizer

Refurbishing Guide

Extracción del bisel

Slice through adhesive sealing the top edge of the bezel, and then cut the top bezel open with the Cutting Nipper.

TP Separating

separate the TP flex cable and the display flex cable first. Set the LCD Cutting Wire to the gap between TP and OLED. Keep pulling the wire back and forth to separate OLED from TP and the glass lens.

Quitar pegamento

Place the OLED into the adsorption mold and remove residual glue with the Electric Glue Removing Device.

Laminado

Put the OCA+TP laminated glass lens into the bubble removing machine. Take it out and make sure there is no bubble inside. Attach the OCA+TP laminated glass lens to the OLED, and then adhere the TP flex cable to the right position. Place the OLED screen assembly into the laminating mold. Next, put it into the laminating machine. Once finished, solidify the OLED screen assembly in the High Power UV Lamp for 3 minutes.

Prueba

Get the OLED screen assembly connected. Run function test.

Get Free Gift From SHOP.REWA.TECH. Buy any of the products below and get a free refurbishment course. For more information about this Promo, please contact your account manager.

For more details on this Refurbishing solution, please go to Canal YouTube de REWA.